Due to combination of trust, good faith and joint desire to finish the build QSP – Martyn and I agreed on the project overspend and finish the work on a fixed budget. The main overspend was on the foundations which no-one could have forseen and the cladding, which became a lot more costly and time-consuming from the april design and budgeting.

QSP have re-energised the build and are pressing ahead on a number of fronts: cladding, roof, render, drainage …

Kompass the new windows company have had a second site visit and their deposit paid (dont tell the credit card co). Despite having me over a barrel and to their immense credit, the price is a little lower than Rohaus’ which helps with some of the deposit I’ve lost.

I’ve picked up half the bathroom materials from ibath .. decent folk .. so will be able to play at plumbing over xmas after my travels.

So, all was settled on Friday and I was winding down .. for the joiners to blow up and walk off site. Martyn then terminated them and has already arranged other joiners to pick up the project.

No pics again as not enough to show. Not a single piece of cladding went on the building this week. Joiners are no more. Coincidence ?

I head off the Kazakhstan where there are no comms (unless I turn my phone on).

wk 27

Its been very difficult to summon the enthusiasm to write an update ‘cos there’s been a series of calamnities that has virtually ground the build to a halt and cost a fortune. Before I drive anyone to pick up a rope the one good bit of news is that we have some accoya cladding on the walls and it looks superb. So, where do we start:

Weather:

The sheffield region has had the worst weather in perhaps 10 years with extensive flooding, the River Don bursting its banks, 1000’s homes abandoned. Last thurs saw 100mm+ of rain in the day when the monthly average is 90mm. We are fortunate that the plot is on a 15o slope so the water has flowed down the field, across the garden, through the house and under the static caravan. At the same time the house is sodden with only a third of the roof on, and I am concerned that the exposed wood roofs and floors are getting damaged. The joiners perserverve in miserable weather, all credit to Jimmy and the lads for sticking with the work when I’m sure they would prefer a warm cosy shop-fit.

Windows:

This is a story in its own right .. the FUXXERs go bust. After extensive research in June I chose the Reynaers window system and Rohaus to manuf/install. I went with Rohaus thinking they would be the safest bet as a larger one-stop company and handed over a £34k deposit in July. Martyn at QSP rightly would not touch a 50% upfront deposit with a barge-pole so I took it on paying by credit card. I hope to see most of the money returned but its above the consumer credit act levels.

All structural openings were ready mid-sept and we requested the survey to measure the detail openings. They dithered and faffed and finally measured 2 wks later, they then continued for fuk about ’till we got the results of the survey a further 3 wks later and they lied stating they had ordered the glass. A week later I got increasingly frustrated and constantly tried to email and call the directors. Finally in desperation I rang Reynaers and complained to the Rohaus account manager about the breakdown in trust with Rohaus. Joe assured me all was well with them, but 2 days later Reynears received a letter says Rohaus has ceased trading.

Fortunately I received a quote from another Reynaers agent Kompass and Steve has responded very positively, with a site visit/measure within a week. The aluminium material is mostly available at Reynaers but the manufacturers and installers are booked up and we are unlikely to see the windows before the New Year.

Watch this space, in the best scenarios it will cost 7-10k and a 3 month delay. In hindsight I clearly picked the wrong company, but once the deposit is paid there is nothing you can do.

With this in mind I then chased the garage door I had ordered to find it would be 3 weeks later than first expected. The woodburning fire was ex-stock and 2 days delivery .. haha, no chance, its 12wks. I’ve just ordered all the bathrooms materials with a 10 day delivery .. we’ll see.

Cladding:

QSP costed the cladding on the design information provided back in April. It transpired the architects had not designed in sufficient detail and had not considered the vertical weight of the cladding system. Significant further fees were paid for a complete design with a resulting potential doubling of the build cost and time. We are months and 10k’s of cost behind plan.

The corten framework is completed, measured up and some 50 corten panels are being cut and folded as we speak for install in a couple of weeks.

Most of the accoya framework is done but there is a lot of faffing required as build tolerances between the windows and floors have to be taken out to fit vertical cladding (advice – go horiszontal!). Accoya is just about the most expensive cladding material available but it is eco, superbly engineered, no maintenance and a long life. Unfortunately in unpacking the accoya to fit we have found up to 50% of the cladding is warped and unusable. The timber merchant and accoya manufacturer have been out (‘never seen anything like it guv’) but its added time and cost again.

First Fix:

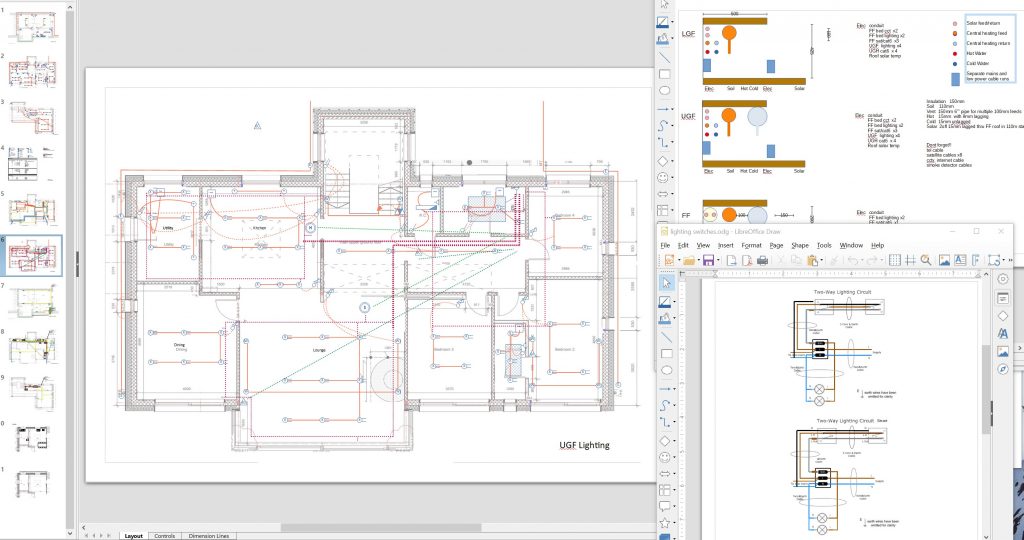

The sparky I first agreed to work with is no longer interested so I’ve found some-one else. The plumber is not returning calls. I’ve lost patience and have done 80% first-fix electrics and 40% plumbing. This, with stud walls built and pocket door frames installed (Eclisse .. pleased with them) some progress has been made on the internals.

Due to the issues QSP and I have now have serious problems in project and cost overruns that we must resolve and get the build revitalised at the worst time of the year.

Its clear we will be spending winter in the static so we picked up a load of carpet offcuts from Mintons and spread them all over the van.

Like an idiot back in March I naively thought the build would be coming to a close and booked a big ski touring trip to Kazakhstan. Do I go or not ?? Next week will tell.

wk 24

Some weeks, despite plenty of lads on site (no gals I’m afraid) you see nothing, however at the end of last week it was the opposite .. huge steps forward were visible. All the corten-clad areas have been insulated, battened and measured to cut/fold the corten. The accoya-clad areas have been mostly insulated and covered. Two weeks ago there was relentless rain (see pics) but since then we’ve had 4-6 joiners on-site each day and no delays for weather. We’ve arranged with the Joinery company (Jimmy Lazenby) so lads can work inside in poor weather .. and of course having arranged this we’ve not needed it.

We’ve had a plasterer for a few days who’s done most of the parge coating to the (inside of) the external walls ..suddenly they more like rooms .. and its made the services room such that we can faff inside it. Next job is to board the first-floor ceilings.

Windows were measured up a couple of weeks ago, and, despite some frustrations, are now due in another 2-3 weeks.

I’ve tidied up the elecs a bit so the first floor is in a clean state, done a bit more studwork and installed some toilet frames so we can stud around them. I’ve also bought the garage door (a simple grey door rather than corten) and have spent a few happy hours working out how to integrate the door into the home controls system. Also ordered the (five) pocket doors.

I’ve concluded that its simpler and cheaper to use solar PV for hot water rather than solar thermal so am going to provision some cables for doing this in the future. Despite doing this myself with string and magnifying glass it’ll cost a good grand .. which is a good many years of gas heating. It remains the case that you pay a premium to be an eco-warrior such as moi.

Finally, despite it only being a garage, the Africa Twin has moved into its new home, yeah : )

wk 22

The first floor roof has been on for a week and, with the garage, they look good and watertight. The joinery build-out of parapets, walls and house front is done and its now all about the insulation and cladding. This is gonna be a looong job as it needs: steel plates to the wall to take the vertical weight, 150mm insulation, breather membrane, jesus bolts, vertical battens, scalloped horiz batterns, fly screen, mesh and we then get have to measure the corten cladding to be cut and shaped off-site (4 wks).

The soil pipes and bathroom ventilation systems are fully installed from the undercroft thru the first floor roof. Electrics are on hold pending Lois engaging.

The garage is looking rather cool, with the ceiling boarded and plastered, and 2 coats of paint throughout. Ang keeps saying ‘its only a garage’ .. sigh, the sheer naivety of her not understanding the importance of the toy-box.

Its become clear the program is now over a month late from the original schedule made in march, c’est la vie. Alan, the site-manager has booked his xmas dinner with us. It means we have all the exterior cladding work going on into the autumn .. but then surely it won’t be as wet as the summer .. hmmm. The other implication is we’ll – or more likely I’ll be living in the static through the winter and we wont get into the house ’till the spring. More positively we are making progress with the second stage of the build going on in parallel with the cladding. Lots of decisions on the fit-out are now arising, from toilets thru skirting.

My sanity is maintained as I write this in the dry sun, having escaped for a week into Ibiza (for the second time!).

No pics this post .. its too miserable looking at a v wet site.

wk 20

Few weeks go by and, for once, I dont see a lot of progress despite roofers, joiners, brickies, scaffolders and QSP on site. I think is going to be true for the next period as we start all the insulation and battening for the cladding … there’s simply a lot of work in preparation. There’s an awful lot on insulation on-site!

We are part-way through the first floor roof .. yeah some of the house (the eastern end) is reasonably water-tight. The insulation and membrane went on in a day (after a day on hold for rain) but then we’re part way thru four further days of detailing of parapets, gully’s and water outlets.

Joiners have been busy on boarding out the parapets and building exterior walls around the first floor bedroom.

I’ve put in soil pipes, ventilation system and first-floor wiring. Hooray for engineered joists, they make life so easy for fitting out. I’ve also put in some of the FF bathroom studwork .. and of course the bathroom design changed once we could walk around it.

Scaffolders have moved all the house scaffolding away from the walls so they can be insulated and battened.

and .. I can see the garage with all the scaffolding removed. Its a big bugger : ) and I’m thinking of the boarding and fitting out. The corten garage door didn’t work out as too expensive but in the meantime hormann and others have released ‘rusty steel’ finishes.

wk17

Yeah, 17 weeks in and we’ve (they’ve!) built to the top of the house (and garage). The scaffolding is up at roof level, the steelworks are all in, the brickies have finished, the joiners are finishing the roof joists and decking and the roofers start next week. We head back down the house over the two months with roofs, cladding and then lots of detailing finishing off. And the next year or five finishing off.

We had a bit of a issue on the cladding with a 10k+ overspend, primarily on stainless brackets to take the vertical weight of the cladding. Overspend was rejected and everyone had to knuckle down and come up with a more cost-effective solution .. which we have. It’ll all be plain sailing now .. er .. right.

As normal .. I now realise, we see days on great progress with walls, steelworks and roofs shooting up, days were you see little progress as its detailing finishing and preparing for the next stage, and days of no progress .. when is blxxdy raining.

I’ve been a sparkie the past week and have most of the first fix of electrics in, grinding out back boxes was filthy work but done quickly with the right kit. Think I’m up to 5km of cabling.

Kitchens design is settled, bathrooms ok except we cannot find a layout for the first floor that we like. We’re having to start thinking of interior design .. we need to add the quirkiness that we want to the house, but I’m struggling as my brain is full of the build and first fixes.

wk15

Another couple of weeks of steady progress, although it rained and it was friday today .. so the brickies and the joiners had the day off.

The brickies are nearly finished, the garage and the first floor have been build and their only work left is to finish off when the steelworks are all in .. and a bit of tuning as I’m tweaking the windows. It escaped me that the first floor bathroom windows are at shoulder height so we’re going to chop a couple of courses of blocks out to let Ang can see out of them.

The joiners are now the main trade on the build. They spent the past couple of weeks building up the UGF ceiling – joists, laying the firrings and boarding ready for the roof. There are 3 more roofs to do and then all the wall joinery and cladding .. literally a couple of months of work.

The crashdecks have done their job and are coming out. The scaffolding needs a final lift to the FF roof. The garage steelworks are now in .. it needed a good faff to level up as the brickies work to +- 20mm on blockwork which meant all the corners were a few mm out.

Its good to see the internals of the UGF, the local ashlar stone in the hall is a nice touch and I love the look of the large windows throughout. We can now look out of the first floor window (well – a hole in the wall!) into the garden and beyond.

I’ve spent inordinate time planning all the services to the house, plumbing, the kitchen/util/bathroom ventilation, the electrics, smart-lighting wiring, the services riser, ‘t internet and the burglar/fire alarm. The sheer volume of bits to think of has left my atrophied brain bewildered.

I’ll have a little rant on security/fire alarm systems .. the ‘smart’ alarm systems are all wireless, but the building regs require fire/smoke detectors to be wired powered and interconnected. This drives you to the ‘professional installer’ alarm systems but these are prehistoric in smart-home capability. I know what I want .. a UK hybrid intruder/fire system supporting IP access, a phone app and MQTT into HomeAssistant. but I haven’t found a solution yet.

Much discussion has taken place on the accoya and corten cladding .. we have detail design and now need to see if its build-able. I visited a superb little company yesterday that do corten paint .. and I now plan to paint the whole house, and Ang, in corten .. v exciting 🙂

wk13

Time flies by when you’re having so much fun. Half way through the planned build and we’re ahead of schedule. Weather has held up reasonably well the past few weeks.

The groundworkers have finished for the time being with all the services laid between the house and garage. There was a huge lump of old concrete to dig out that needed a bigger digger and some rework but all completed. They return near the end of the project when the rain pipes are in and the site is cleaned up.

The brickies have the upper ground floor done and 80% of the garage. The scaffolders seem to be around 3days/week to keep up with the speed the walls are shooting up. Final bit is the last 50% of the first floor.

The steel beams supporting the lounge and other areas of the house went in last week with the assistance of a 40t crane. Naturally they needed a bit of fine tuning – cutting and welding fixed that.

There was a big transition last week moving from groundworkers and brickies towards roofers and joiners. Crash-decks were put in the house and we’re seeing the ceiling and roof joists going in with the joiners back on the job.

Windows have been ordered following a last minute flurry sorting out background ventilation.

LGF electrics and plumbing is 90% in place and I’m now waiting for the UGF ceiling to be on before I can do more first fix.

Kitchen/Util room design is more or less nailed and we working with 2 companies on details and quotes.

wk 10

After a couple of weeks of good weather the house is shooting up and we’re -even- running to plan. The brickies are pushing up the blockwork for the walls, I think we had the scaffolders in three times this week to raise the scaffolding to cope with the pace of the brickies. We’re at upper ground floor (UGF) ceiling height around most of the house so can now see how it going to look. The utility room looks a bit small but other than that we’re really pleased with the layout, and the tall (2.8m) windows and room height looks great.

The groundworkers have made good progress with the services through 3/4 of the house and are ready to lay the main garage slab.

The joiners started last week and have laid the joists and floor for most of the UGF. Roof timbers have been ordered.

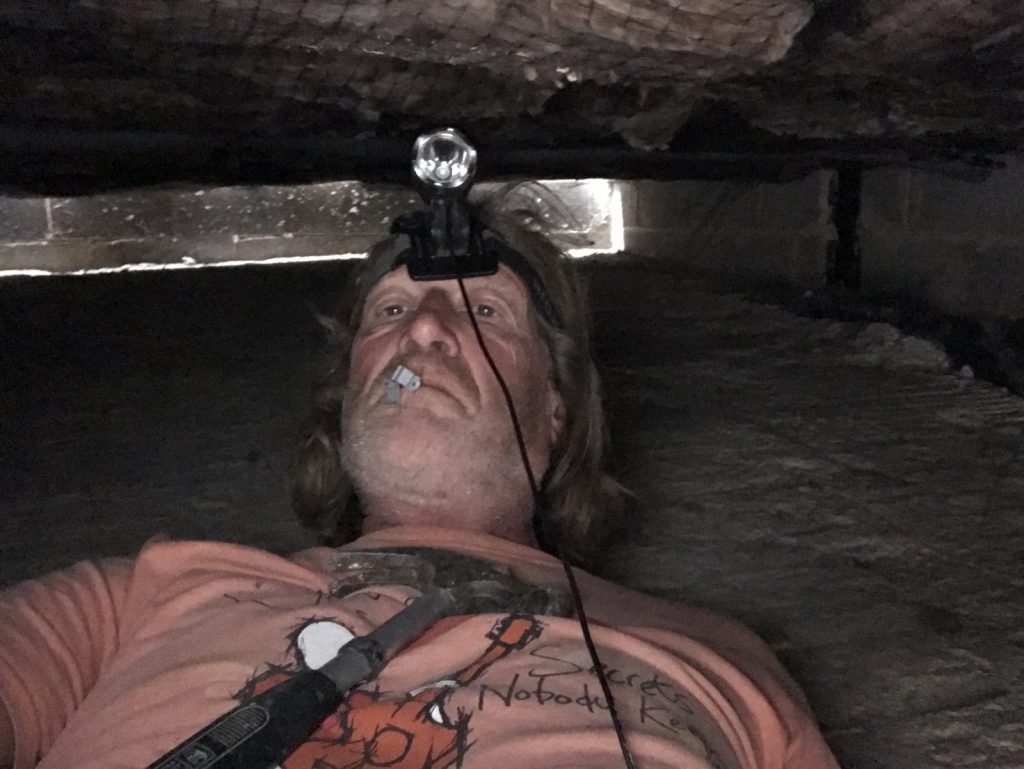

As the UGF joists were placed I’ve been putting in the first fix electrics and plumber has helped with some of the drainage. The S end of the undercroft would have needed a pot-holer to crawl around so timing was great and its good to get my hands dirty.

A good amount of discussion solved the detailing of the exterior – cladding, corten, windows. Mike (the architect) suggested changing to cladding to horizontal but soon understood that was not going to fly.

Windows are virtually resolved with a couple of visits to potential suppliers to nail to final specs (eg single-slider on doors for cost, all glass laminate for security, background ventilation) and we realised paying the upfront costs by credit card allows them to purchase materials yet gives us security if it all goes horribly wrong.

More progress with kitchens, a few options of suppliers are being looked at and we have a pretty good view of the floorplans. Design ideas have moved on for kitchens e.g. as we want a elegant minimalist kitchen to flow through to the lounge we’re have no wall cupboards but placing the appliances in mid-size (1.4m high) wall units.

wk8

A week and a bit of steady progress. The foundations are complete and the blockwork is going up around the house .. we’re at head-height through most of the house and the scaffolding is in place to move upwards. Groundworks have started installing the drainage.

Invoices have surfaced for the foundations redesign … fuk.

Windows have come back to bite us, their t&c’s mean we are expected to pay upfront (£60k or more) without seeing anything .. and QSP have had two companies go bust in them in their time. I don’t think we can escape some stage payments but we need to find a company we can trust.

We got quotes in for the staircase and balustrading .. with a 3x range of prices. They don’t go in ’till the end of phase1 but we wanted to check whether they require anything now eg padstones, steelwork. The two we talked to would rather sort it out when we’ve built the shell.

We’ve started thinking of the kitchen and have approached a couple of companies for their design inputs and budgets. Not v impressed with their responses but at least we are getting our heads around the design.

QSP have revised the build plan which a/ pull the timescales back in after slipping 2 weeks in 8 (foundations and bad weather) and b/ give us access to the house earlier to do first fix elecs and plumbing.

I’ve started to work with a sparkie and plumber .. gawd help ’em.

We matured the design and fixing of the corten cladding, the devil is in making it water-tight

The home-controlled static caravan is working reliably .. even Ang is using it (the iPhone-app’d, home-controlled, internet-accessed, wirelessly-enabled electric blanket provided the incentive :).